Types of tees

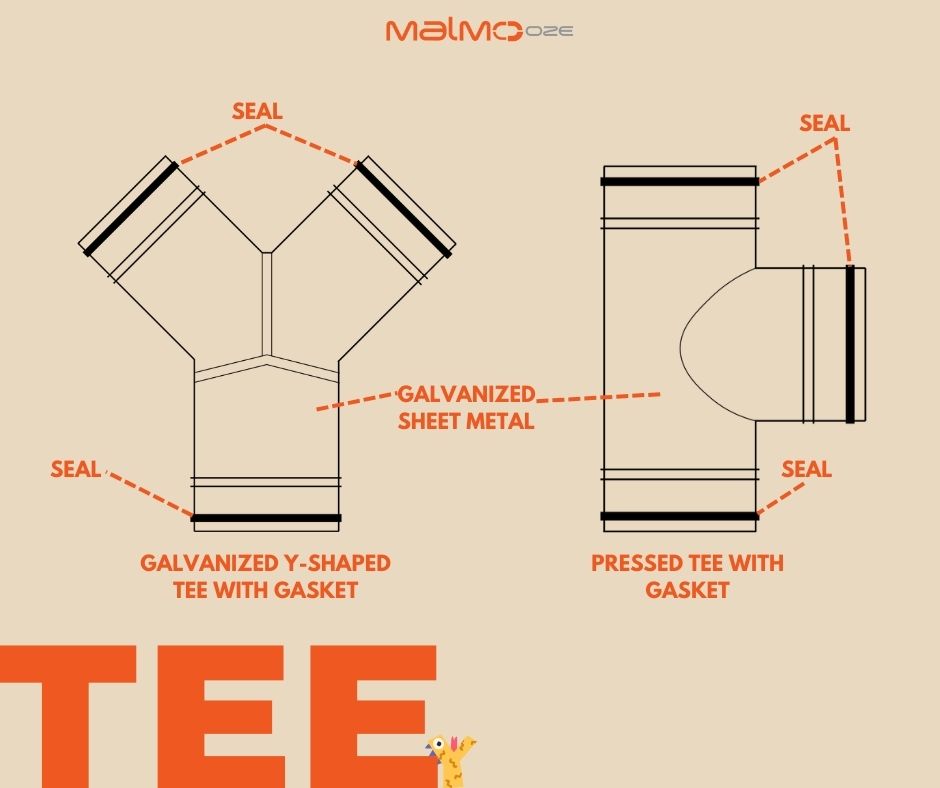

Galvanized Y-shaped tee with a gasket and a 90° pressed tee – how do they differ and when to choose which one?

Both are used to distribute air flow in ventilation systems, but they differ in the angle of departure and application.

Galvanized Y-shaped tee with gasket

– Divides the duct into two branches at an angle – usually 45°, but there are also 30° and 60° versions.

– It works well where air needs to be distributed smoothly and evenly in two directions – e.g., from the main duct to two rooms.

– It is available in versions with equal pipe diameters or with an inlet larger than the outlets.

Trójnik tłoczony 90° z uszczelką

– Distributes air at a right angle – one outlet goes straight, the other goes sideways at a 90° angle.

– It is a universal component that works well in both domestic and industrial installations.

– Thanks to factory-fitted seals, installation is quick and tight – no additional sealing is required.

90° pressed tees are also available in reduction versions, which makes it easier to match them to different pipe diameters.

Materials and diameters

– Galvanized sheet metal is most commonly used, but variants made of aluzinc, magnelis, aluminum, and acid-resistant steel are also available.

– Typical diameters are 125, 160, and 200 mm, but smaller and larger ones are also available, e.g., 100, 140, and 180 mm.

Seals – tight, but no overdoing

– In both Y-shaped tees and 90° pressed tees, factory-fitted seals ensure tight connections and speed up installation.

– However, it is important to remember that the gasket must be correctly installed – it should not just be stretched like a rubber band.

– It is best when it is located in a rolled-up end or secured with a steel band (e.g., a sleeve connector).

Pressed vs segmented

Pressed – made from a single piece of sheet metal, they offer lower flow resistance

Segmented – assembled from several elements, easier to manufacture, but cause greater pressure drops

In the case of segmented systems, it is important to provide additional sealing at the joints, otherwise the system may not achieve the required tightness class.